Now Reading: 3D Printing Breakthrough: Titanium Rocket Parts Take Shape

-

01

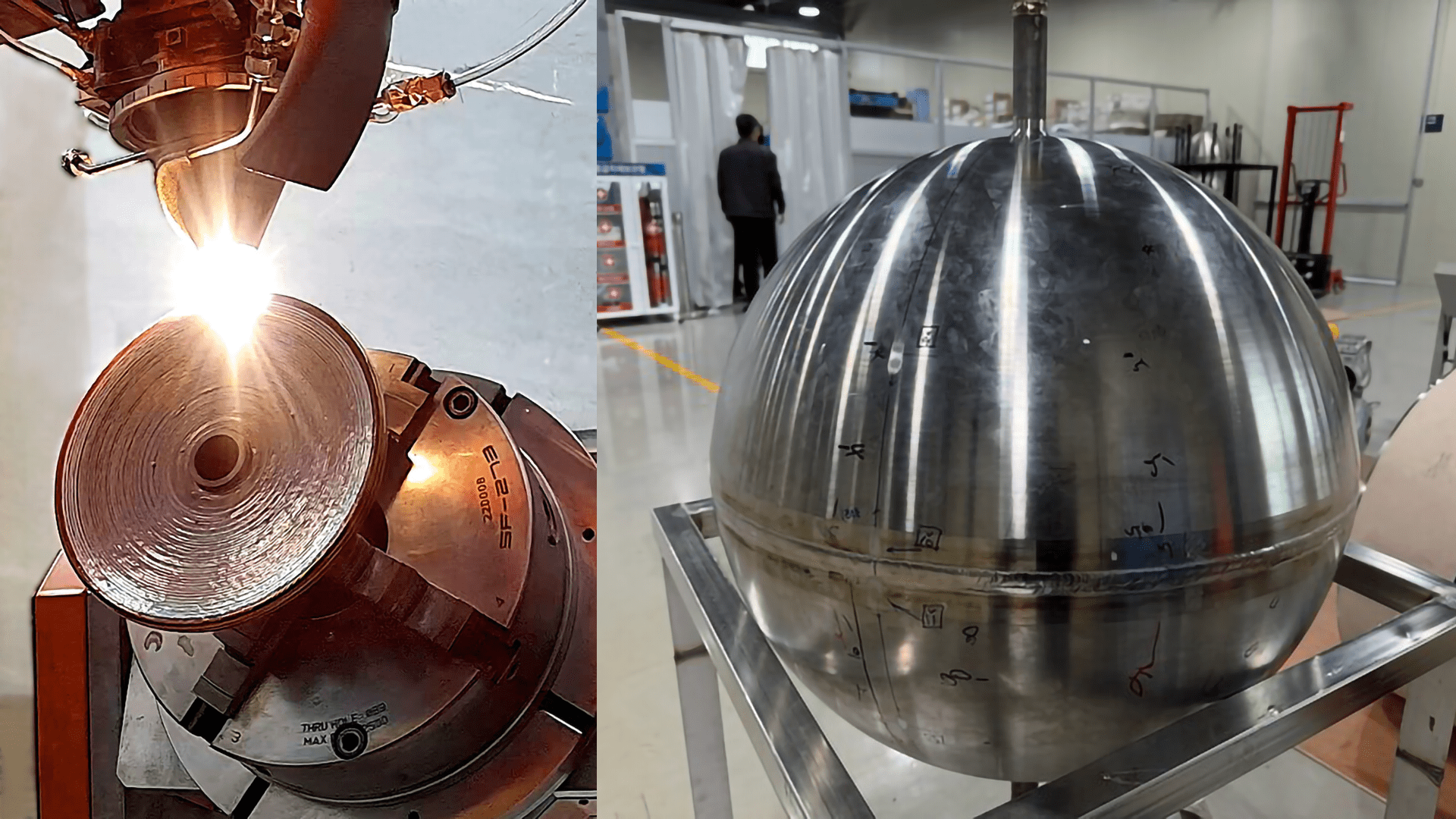

3D Printing Breakthrough: Titanium Rocket Parts Take Shape

3D Printing Breakthrough: Titanium Rocket Parts Take Shape

Rapid Summary

- The Korea Institute of industrial Technology (KITECH) successfully tested a 3D-printed titanium fuel tank for space applications-marking a world-first achievement.

- The tank, made from Ti64 titanium alloy, measured 640mm in diameter and withstood extreme conditions: -196°C temperatures and pressures up to 330 bar during testing.

- Developed as part of a collaboration with the Korea Aerospace Research Institute (KARI), KP Aviation Industries, AM Solutions, and Hanyang University.

- Traditional forging methods for manufacturing similar high-pressure vessels face challenges such as long lead times (6 months-1 year) and reliance on imports from Ukraine due to limited domestic facilities.

- A new Directed Energy Deposition (DED) 3D printing process reduced production time to three days plus post-processing, offering faster customization compared to traditional methods.

- Overcoming skepticism about safety risks associated with using 3D printing for high-risk components like pressure vessels was crucial in this breakthrough.

- This advancement strengthens domestic supply chains while boosting private-led initiatives in space research under the ‘New Space’ era.

Indian Opinion Analysis

The triumphant cryogenic pressure test of KITECH’s 3D-printed titanium fuel tank represents an crucial step forward for global aerospace technology. For india’s burgeoning space sector-managed by ISRO and private players-it underscores the potential benefits of incorporating additive manufacturing techniques into rocket component production. Challenges associated with reliance on imported parts or drawn-out forging processes are similarly relevant in India; thus, these advancements could inspire local efforts to build resilient domestic supply chains.

The implications go beyond technical efficiency; shorter growth cycles introduced by technologies like DED printing would enhance responsiveness to changing mission requirements-notably valuable amidst increasing competition globally. As India pushes toward privatization under its own ‘New Space’ ambitions, fostering collaborations similar to KITECH’s model may ensure sustainable growth without compromising quality or reliability standards critical for space missions.

read More: https://www.popsci.com/science/3d-printing-tackles-titanium-to-create-rocket-parts/