Now Reading: SpaceX Unveils New Grid Fins for Super Heavy Booster V3

-

01

SpaceX Unveils New Grid Fins for Super Heavy Booster V3

SpaceX Unveils New Grid Fins for Super Heavy Booster V3

Speedy Summary

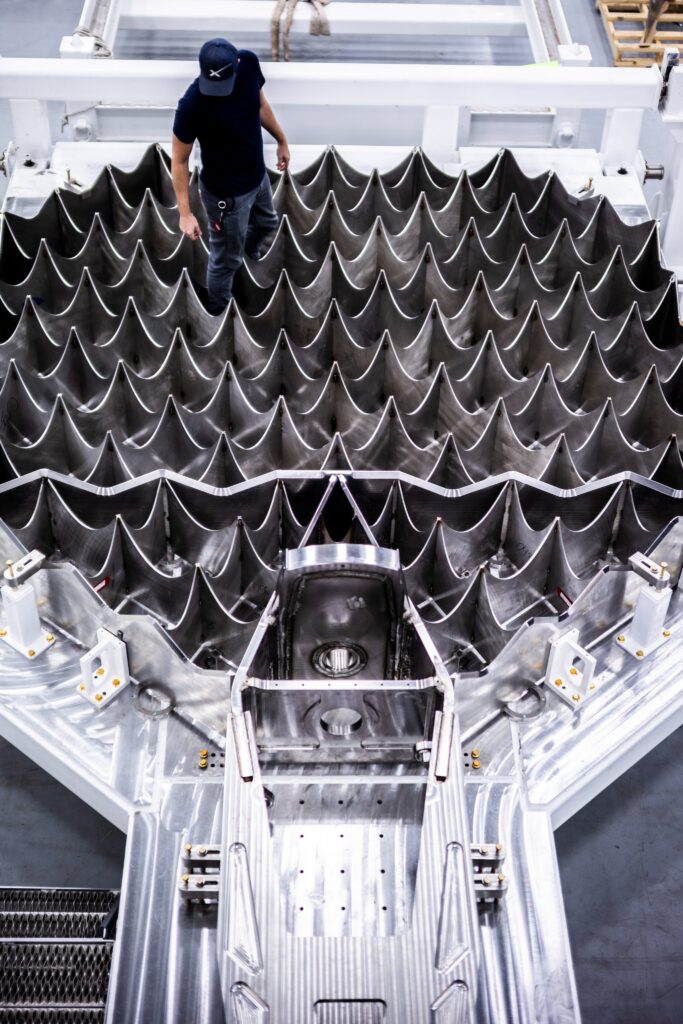

- New Grid fin Design for Super Heavy Boosters:

– Reduced number of grid fins from four to three, arranged in a T-shape. Each fin weighs approx. 3 tons.

– Increased size by 50%, with enhanced structural strength for vehicle control and heat distribution during reentry.

– Relocated fins lower on the booster, aligning with tower catch arms for direct “catch” operations and reducing heat exposure during hot-staging.

- Key Upgrades on Super Heavy Booster V3:

– Taller design incorporating integrated hot-stage dome and revised chine setup for better aerodynamics.

– Propulsion system switches to Raptor 3 engines, improving reliability, performance, and engine layout to protect flame diverters.

– Increased propellant capacity (25%) and payload capability (up to over 100 tons reusable mode; expandable further).

- Notable Enhancements:

– Improved aerodynamic stability during descent at high angles of attack. Enhanced reusability via rapid turnaround without landing legs using launch tower “chopstick” arms.

– Refueling solution via docking system enables complex space missions (e.g., Mars landings).

– On-orbit refueling readiness highlights future scalability.

- Operational Outlook & Next Steps:

FAA approval pending for next flight test after addressing prior issues encountered in June anomaly. expansion to new launch sites targeted by late-2025 aims at higher Starship mission frequency.

indian Opinion Analysis

SpaceX’s advancements in grid fin design and booster technology demonstrate significant leaps toward achieving higher-cost efficiency, rapid reuse cycles, and mission flexibility in commercial spaceflight operations-a key benchmark that could have cascading implications globally.

for India’s growing space ambitions under ISRO or private players like Skyroot Aerospace, such technological innovations set approachable benchmarks but also underline challenges of competitiveness amidst SpaceX’s lead in cost reduction per payload kg through reusability enhancements like these mechanical integrations. The emphasis here shifts not just toward imitation but mastering affordability around indigenous growth pipelines alongside parallel tech scaling towards self-reuse integration readiness